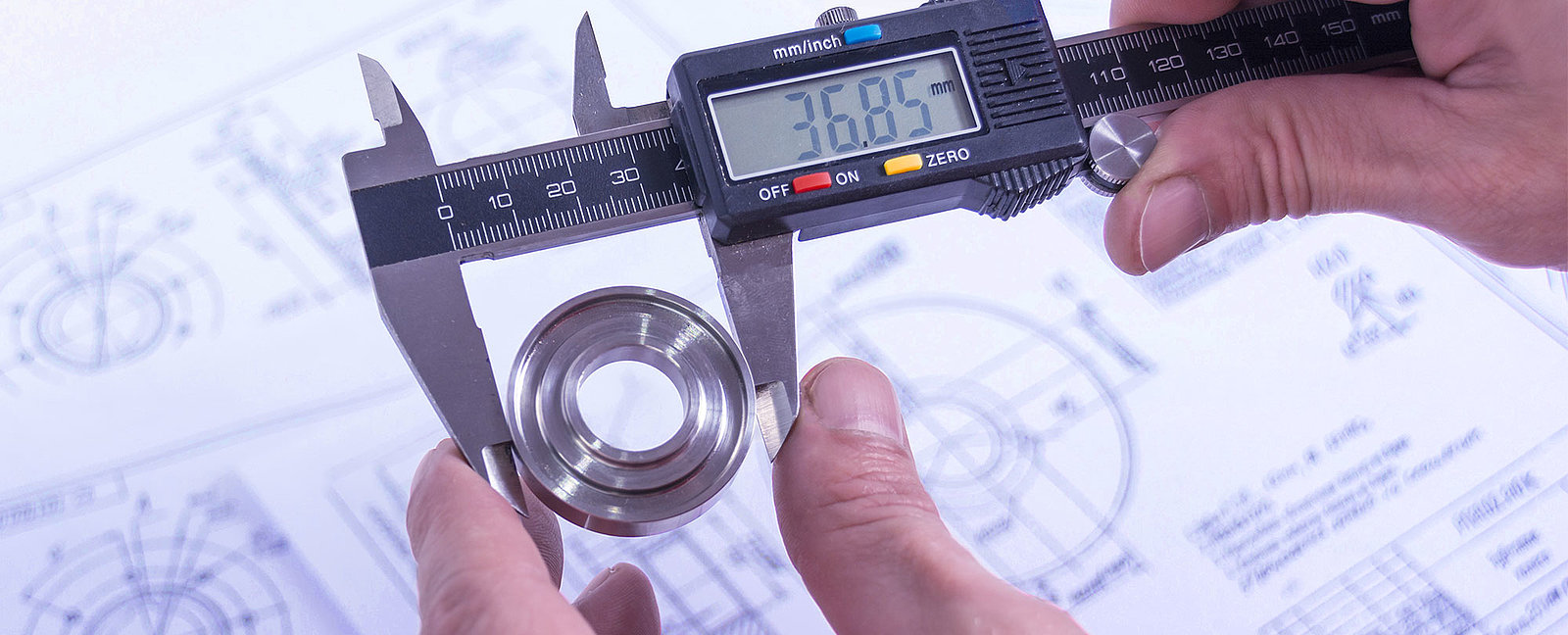

Through regular inspections along the entire manufacturing process, we identify defects at an early stage, thus complying with international norms and standards.

We assist you with in-process inspection at any point along the production cycle and handle communication with the authorities on your behalf. Cooperation with our experienced specialists and inspectors ensures decisive efficiency, especially with regard to lengthy approval procedures.

Our services for you:

An indispensable instrument of industrial quality assurance is non-destructive material testing (NDT) during the entire manufacturing process. Our inspectors have many years of experience and have earned a large number of NDT certifications. To your advantage, we offer all inspections from a single source. We provide specifications, test instructions as well as final documentations for the respective project.

MIAG has a strong focus on the supervision of transport and storage cask production for spent fuel elements. We undertake preliminary reviews of technical documentation, on-site inspections, reviews of modifications and deviations, as well as the supervision of manufacturing documentation. We also compile comprehensive construction supervision reports.

In addition, we perform administrative tasks and support you in the realization of your project.

Guidelines according to:

(Picture credit: "GNS Gesellschaft für Nuklear-Service mbH")

Safety testing, Level 2 and Level 3 certifications in common NDT methods: Ultrasonic Testing (UT), Magnetic Particle Testing (MT), Penetrant Testing (PT), Digital Radioscopy (RT), Leak Testing (LT) and others.